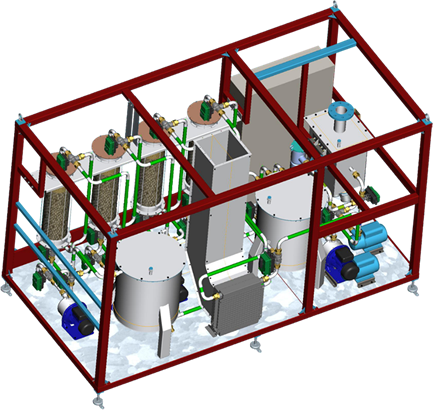

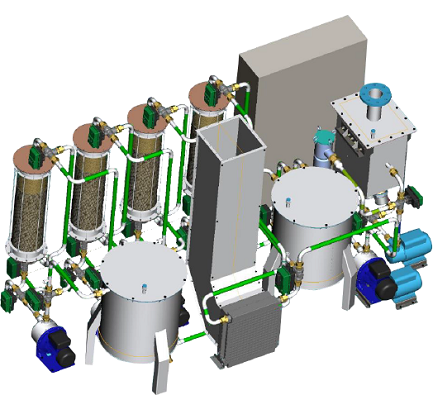

SISTEMA DI TRATTAMENTO ACQUE REFLUE AD ALTO CONTENUTO DI C.O.D.

Description

Wastewater, stored in appropriate tank, is loaded automatically by a pump and introduced into the heating tank; the loading phase ends at the acheiving of the volume (50L), when the level sensor stops the pump load.

The heating takes place by means of electrical resistances immersion the operating temperature is about 100 ° C; this temperature is maintained thanks to the inputs generated by the temperature control of the tank. In the tank there is installed a shaker with the purpose of ensuring a uniform distribution of heat throughout the mass of water. The heating takes about 30 minutes. This phase allows to degrade all the thermolabile substances and eliminate much of the volatile substances.

The tank is airtight but not working in fact the vapor pressure generated during the heating phase are conveyed in an activated carbon filter (in this phase are eliminated as all volatile substances; solvents, formaldehyde, chlorine, etc.).

Once the heating phase the wastewater is discharged from the tank and transferred to a second tank. First it is filtered through a filter bag nylon monofilament mesh porosity equal to 5μ In the secondary tank the wastewater is mixed with 25L of running water; this allows a rapid lowering of the temperature also with a dilution effect increases the efficiency of the exchange with the resins (which prolongs the life of the resins).

This tank is connected with a heat exchanger to air, by means of appropriate valves you create a recirculation loop. The effluent continues to flow in the heat exchanger and is discharged into the tank to then be reloaded in the heat exchanger and so on. This cycle continues until the temperature control inside the tank does not reach a temperature below 35° C. Reached this value the loop is broken and the wastewater treatment process continues.

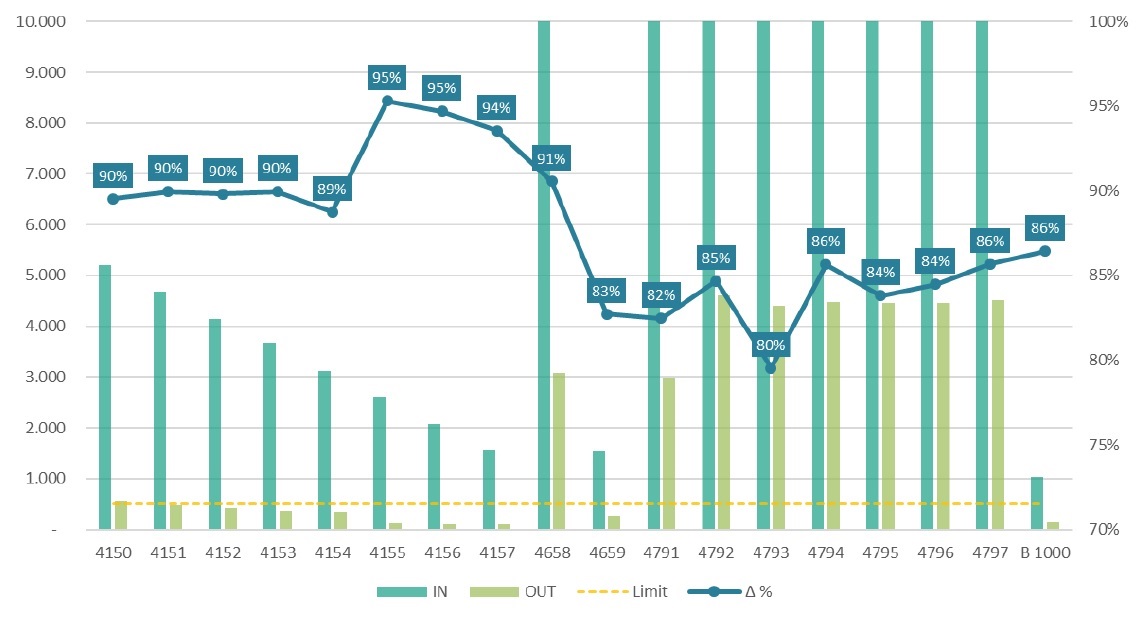

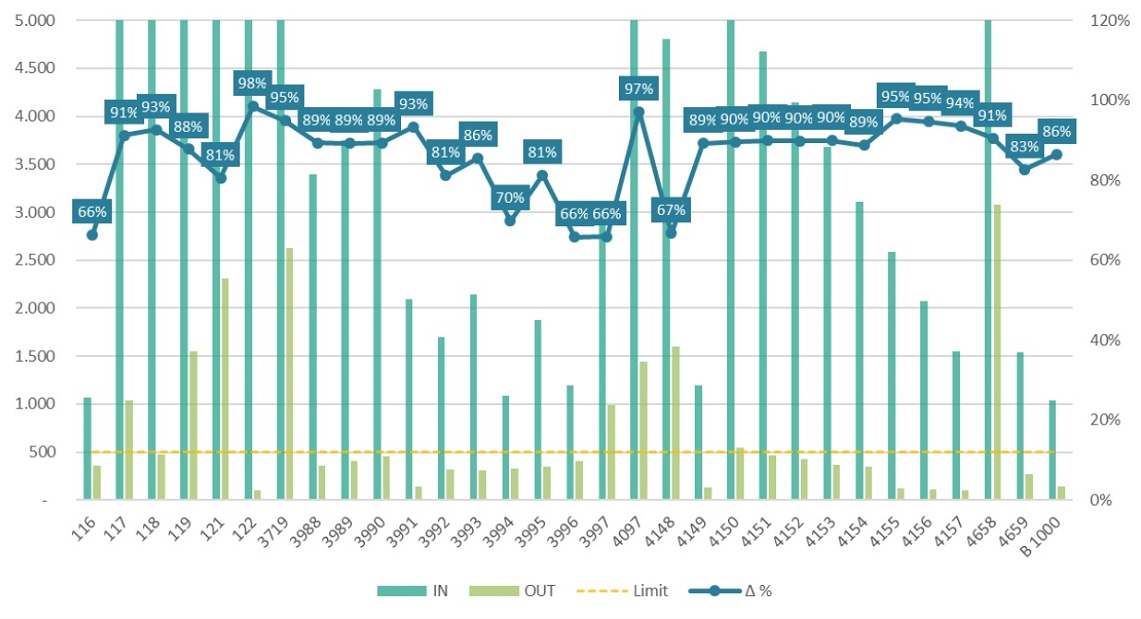

C.O.D. 1st Series

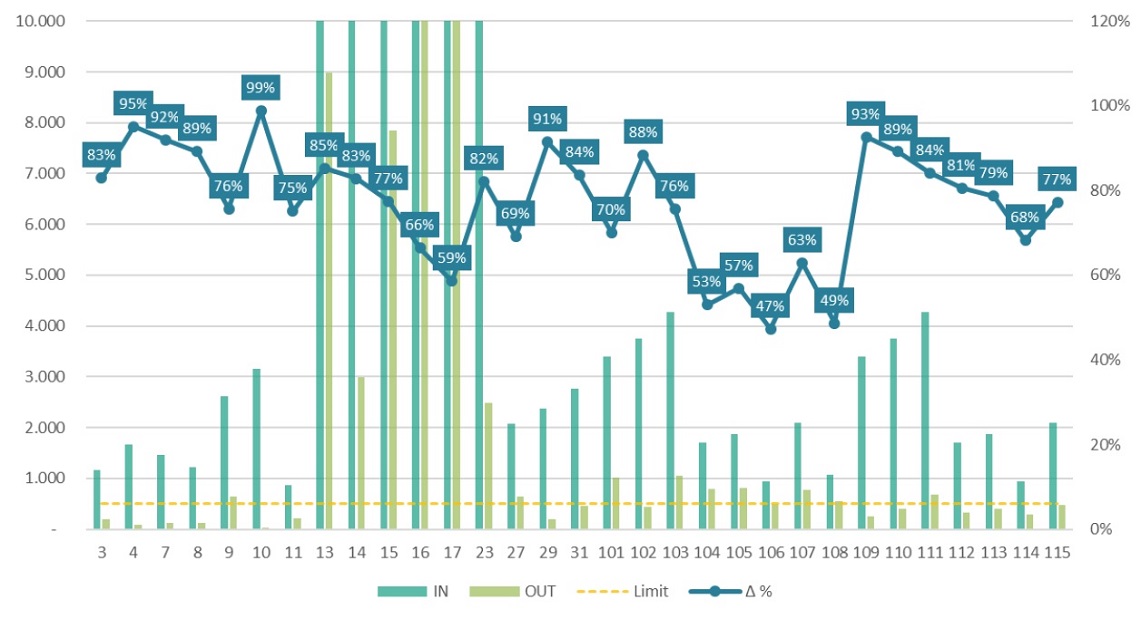

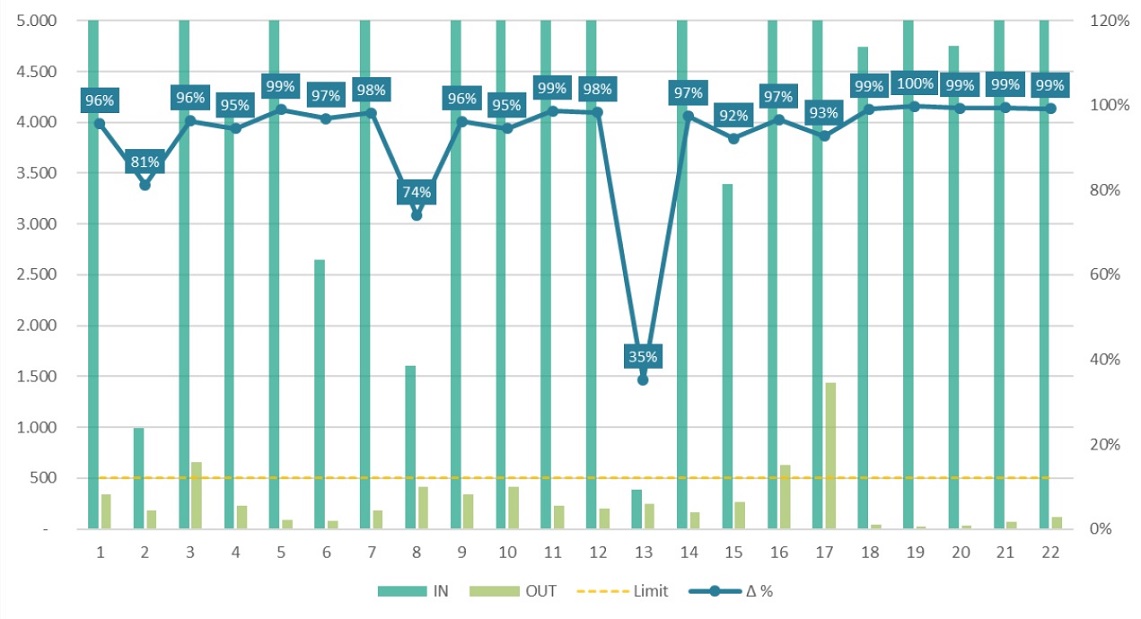

C.O.D. 2A Series

C.O.D. 2B Series

C.O.D. 3rd Series